Description

The particularly comprehensive range of applications in the field of “medium-heavy duty sewing” often takes the used machine technology to its limits. The continuously increasing demands with respect to extreme thread and fabric thicknesses as well as a multitude of most different materials require very robust and high-performance operating means.

At the same time the working processes are expected to be executed with maximum efficiency and profitability. This requires outstanding technical performance parameters and the possibility to use automatic functions.

The subclasses of the H867 have especially been designed to meet these demands. The robust construction in connection with the impressing performance parameters and the excellent equipment features of the CLASSIC variants make these machines an ideal operating means for demanding sewing operations, especially when processing technical textiles.

Your advantages

• 4 subclasses with highly efficient equipment features in the variants ECO and CLASSIC as single or twin needle machine as reinforced version

• Powerful and effective feeding system with bottom feed, needle feed and alternating top feed

• Up to 12 mm long stitches for standard seams and decorative topstitching

• The extremely high sewing foot lift up to 25 mm facilitates the feeding and removing of bulky workpieces

• The sewing foot stroke up to 9 mm allows the safe climbing over differently high material plies

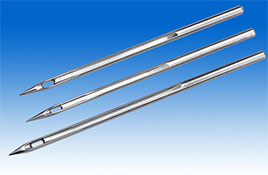

• New hook system with 3XL bobbin for thread sizes up to Nm 8/3 max.

• Max. sewing speed up to 1,800 stitches/min.

• ECO version with electropneumatic sewing foot lift as standard

• Robust thread trimmer guarantees a safe and clean cutting of extremely thick sewing threads (CLASSIC)

• Integrated 6-function keypad with ergonomically arranged favourite key (CLASSIC)

• Equipment features corresponding to the M-TYPE CLASSIC Goldline version like thread trimmer, automatic backtacking, electro-pneumatic sewing foot lift, integrated LED sewing lamp and maintenance indicator